Operations at Sink Mixer Factory are at the forefront of the fast-changing global sanitary ware industry. As kitchens become more functional and design-focused, manufacturers are adjusting to keep up with the new demands. Our factory, located in Taizhou—one of China's primary production hubs for sanitary ware—has responded to these shifts through smarter manufacturing, improved product lines, and customer-centric innovation.

Similarly, the role of the Kitchen Taps Factory has expanded far beyond traditional manufacturing. Today, factories must deliver not just faucets but complete solutions tailored to different lifestyles, regions, and installation preferences.

1. Smart Integration with Modern Kitchens

A major trend influencing the market is the integration of sink mixers with smart kitchen technology. Modern homeowners and commercial kitchens demand features that enhance convenience, hygiene, and water efficiency. As a result, manufacturers are now producing models with:

Touchless activation

Built-in filtration systems

Temperature memory functions

Digital displays for water usage tracking

These upgrades are now possible thanks to advanced R&D and technical capabilities in progressive production facilities.

2. Emphasis on Water-Saving and Eco-Friendly Design

As global regulations tighten around water consumption, sink mixer factories are focusing on environmental compliance through:

Flow restrictors

Aerated spouts that reduce water usage

Recyclable and lead-free materials

Cartridges designed to minimize water wastage

This shift not only supports sustainability goals but also helps clients meet local regulatory requirements in export markets such as Europe and North America.

3. Customization and OEM Flexibility

Buyers are increasingly looking for customization—both in function and design. A capable kitchen taps factory now offers:

OEM & ODM services with short lead times

Custom logo engraving

Varied surface treatments (chrome plating, brushed nickel, matte black, etc.)

Flexible packaging options for different sales channels

This level of adaptability has become a standard expectation among international partners.

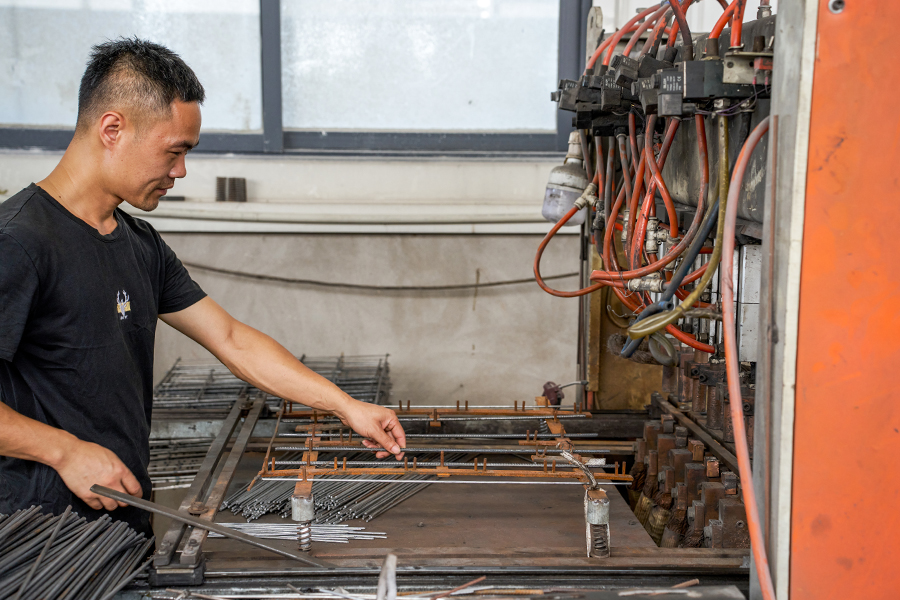

4. Faster Production Through Automation

Factories across the world are investing in automation to enhance efficiency and output. Automation is being applied in:

Die-casting and molding

CNC machining and polishing

Laser marking and assembly

100% water pressure testing

With these tools, manufacturers can reduce errors, cut down delivery times, and ensure a more consistent quality level, even in large-scale production runs.

5. Quality as a Competitive Advantage

In today’s global faucet market, quality is not just a checkbox—it’s a competitive edge. That’s why every sink mixer factory that hopes to compete internationally must implement:

ISO9001-certified quality management systems

Full inspection routines across the production line

Salt spray testing and life cycle testing

Global standards compliance (e.g., CE, CUPC, WRAS)

Our factory has adopted a multi-layered quality assurance protocol to deliver products that meet the rigorous demands of global distribution.

6. Logistics and Supply Chain Agility

International customers expect fast delivery and reliable communication. As such, the operational efficiency of a factory is now measured not just by how quickly it can produce, but how well it can ship. Key logistics practices include:

Strategic warehousing for bulk orders

Transparent shipping documentation

Support for mixed container loading

On-time order tracking and updates

These logistics capabilities allow modern kitchen tap factories to build long-term relationships with clients from Europe, Southeast Asia, the Middle East, and beyond.

At our facility, these industry trends are not abstract concepts—they are embedded in our daily operations. Through continuous improvement and dedication to quality, we aim to serve clients worldwide with products that align with modern kitchen lifestyles and global standards.

Language

Language

English

English русский

русский Español

Español عربى

عربى Phone

Phone

Email

Email